The conclusion of my winter suspension maintenance: 2.44kg of sprung, and 1.01kg of unsprung weight saved. I wouldn't normally go in to such small detail, but when a maintenance job is required I will take the opportunity to optimise or improve whatever parts are involved.

Wheel uprights machined to Challenge spec

Challenge car uprights undergo two modifications:

1) Rear handbrake caliper/front vertical acceleration sensor mounting bosses are milled off;

2) Brake cooling vents machined out.

A road-going F430 requires both handbrake caliper/front vertical acceleration mounts, so I opted to machine the brake cooling vents to save a little bit of unsprung weight.

Standard (360/430) upright:

My uprights (16/Scuderia) after machining:

Refurbished and rebuilt front arms with Scuderia flanblocs

Refurbished and rebuilt front arms with Scuderia flanblocs

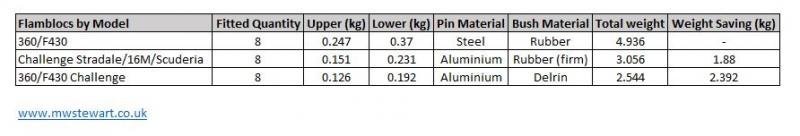

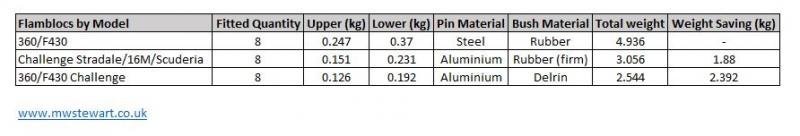

I have in stock each type of flanbloc to investigate their construction and weight. My findings are below:

I sent my arms via courier to AV Engineering to be built up. Great communication throughout - it's nice dealing with someone whom you can trust to do the job well. New HE ball joints, and Scuderia flanblocs.

New CCM discs

New CCM discs

Thanks to my friend Gary I have a set of new front & rear CCMs to go on. These won't save any further weight - the fronts were quite worn but I'd put off changing them because the bite is really good, the downside being that they ate pads! Challenge discs are bed-in during manufacture, which is nice.

Hubs rebuilt with bespoke titanium spindles

Hubs rebuilt with bespoke titanium spindles

I've covered these in a previous update, but these are fitted after being hard anodised.

Camber shims replaced with aluminium spacers

Camber shims replaced with aluminium spacers

As a general guide, the following applies:

Front + 1 mm shim = -0.20 to -0.25 degrees of camber.

Rear + 1 mm shim = -0.30 to -0.40 degrees of camber.

Removing front UCA washers = -0.6 to -0.7 degrees of camber.

Removing rear UCA washers = -0.5 to -0.6 degrees of camber.

I've removed the upper RCA washers

(top right in photo) to gain some camber, and based on that I ran the calcs for my new ride height to determine the thickness of shims F&R, and used that to have a set of aluminium spacers machined

(top left in raw form, and bottom left with etch primer). The weight soon adds up with the steel shims

(bottom right) when chasing a more focused camber configuration - I've saved a shade under half a kg for very little outlay.

Vertical acceleration sensor hardware

Vertical acceleration sensor hardware

Titanium and aluminium fasteners used to save a few grams.

Wheel upright rear cover plate

Wheel upright rear cover plate

I remade these in carbon, used lightweight fastenings, and lightweight cable management clips. 338 grams of unsprung weight saved.

Calibration optimisation

Calibration optimisation

AV Engineering have my ECUs:

360Trev has been undertaking some great work on the Bosch ECUs, and he has discovered many improvements. AV and Trev have teamed up to offer an electronics service, and I can't wait to get these back and in the car: even though my car in its current form is quicker than the 06 F430 I owned, it still lacks some of the punch that car had. I'm quietly confident that Trev can produce some magic.

Weight Saving Total

Weight Saving Total

Unsprung weight saved: 21.59 kg

Sprung weight saved: 111.86 kg

Total weight saved: 133.45 kg